Printing technology has come a long way, and with the advent of digital printing, the process has become more efficient and cost-effective. One of the most important aspects of digital printing is the ability to produce high-quality prints before the actual printing process begins. This is where the printing proofing machine comes in. A printing proofing machine is a specialized printing device that is used to produce printing proofs before the actual printing process begins. In this article, we will discuss the different types of printing proofing machines, their applications, and the technology behind them.

Types of Printing Proofing Machines

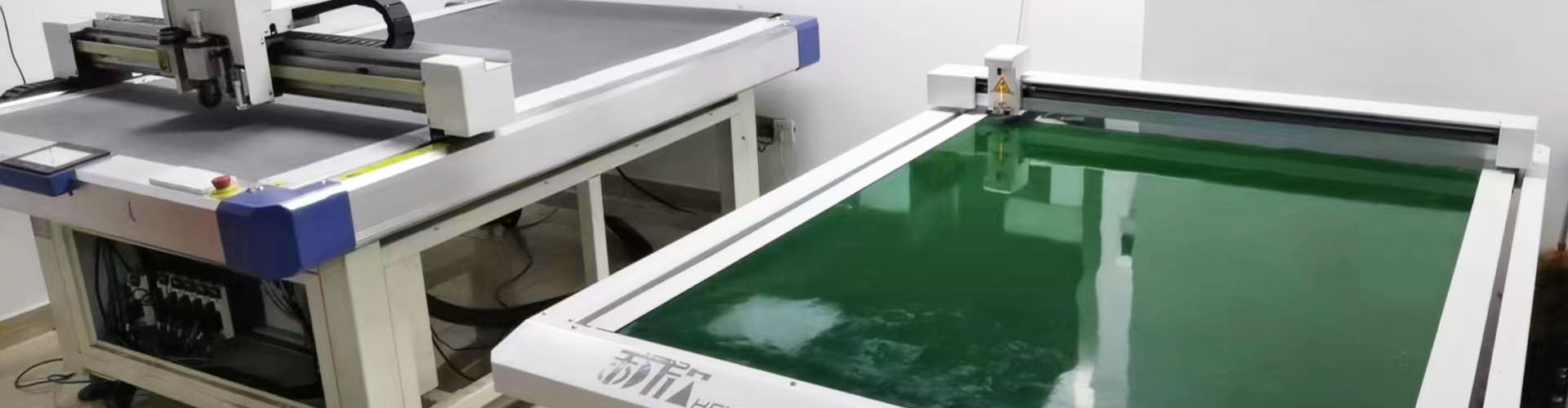

There are two main types of printing proofing machines: universal printing and digital printing. The universal printing proofing machine is designed to print on a variety of materials, including metal, plastic, wood, porcelain, glass, acrylic, stone, bamboo, crystal, building materials, leather, fabrics, oil painting boards, and more. These machines are known as flatbed proofing machines.

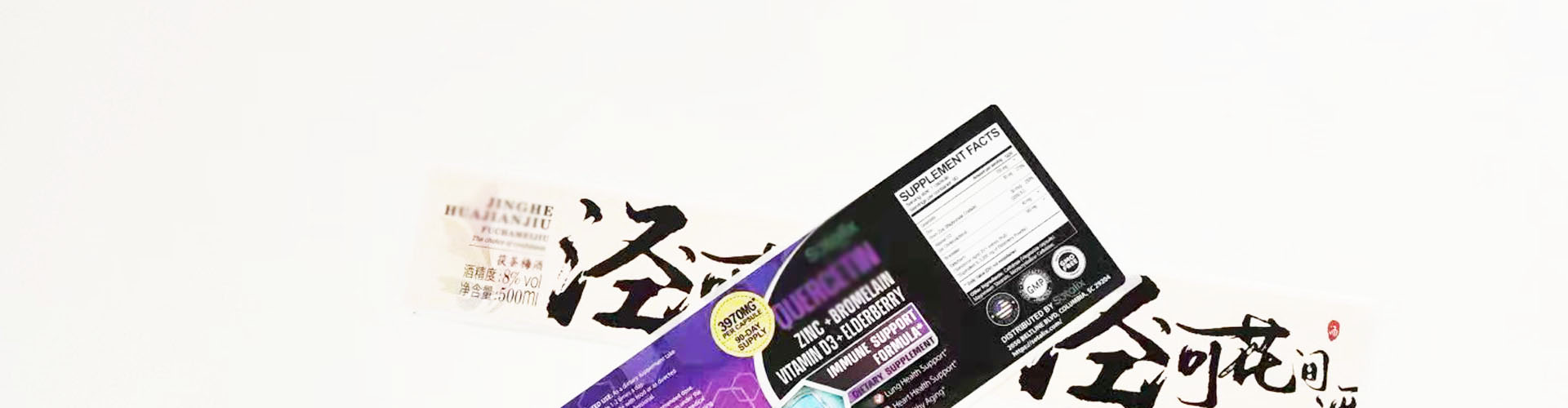

The digital printing proofing machine is designed to produce printing proofs on printing media such as SBS paper, matte art paper, gray card paper, coated paper, book paper, gold and silver cards, laser cards, leather paper, pearl paper, leather pattern paper, ancient paper, sulfuric acid paper, newsprint paper, photographic paper, self-adhesive paper, oil painting cloth, non-woven fabric, binding cloth, chemical fiber cloth, banner cloth, outdoor light cloth, transparent film, car stickers, wallpaper, PVC/PET film and leather.

Applications of Printing Proofing Machines

Printing proofing machines have a wide range of applications. They are primarily used for pre-press printing proofing and digital proofing. They are also used for packaging printing proofing and special media proofing. They can produce high-quality prints for gold and silver cards, PVC/PET/PP film proofing, image/artwork production, POP posters/CAD/GIS output and inkjet plate making. They are also used for leather printing, business card printing, personalized printing and self-adhesive printing.

Technology behind Printing Proofing Machines

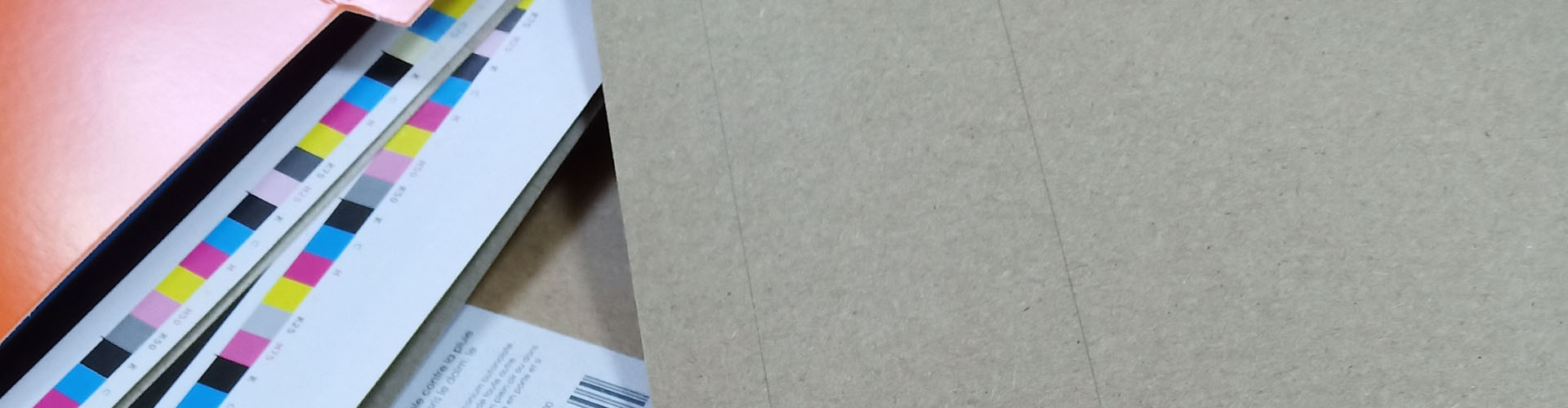

Printing proofing machines use advanced and durable "piezoelectric" inkjet printing technology. They are specially designed to work with printing pigment ink and simulated inkjet printing ink. The intelligent heating system ensures that prints are instantly dry on uncoated printing media. Professional color management software (EFI and CGS software) can achieve true dot output and accurate color reproduction to solve the problem of printing proofing deviation. The machine can produce multi-media uncoated prints without color difference and can compare with offset proofing.

Printing proofing machines are an essential tool in the printing industry. They help to ensure that the final printed product meets the desired quality standards. They are widely used in pre-press printing and digital proofing applications. There are two main types of printing proofing machines: universal printing and digital printing. The technology behind these machines is advanced and durable "piezoelectric" inkjet printing technology that produces high-quality prints on a variety of materials. Printing proofing machines are an indispensable tool in the modern printing industry.

previous post

How to improve excessive packaging?

next post

What printing technology is used for label

YOU MAY ALSO LIKE

What is sustainable packaging

2023-05-05 02:03:21

Customized Packaging Solutions with a Commitment to Sustainability

2023-07-15 07:23:59

Reducing Waste and Increasing Recycling

2023-07-18 04:01:48

Promote sustainable practices throughout the supply chain

2023-07-18 06:35:56

Focus on eco-friendly materials

2023-07-18 07:04:38

The packaging solution tailored for a specific product

2023-07-18 07:32:16POPULAR POSTS