Paper tube, as a type of paper packaging, may appear to be a straightforward cylindrical structure, but the production process is quite complex and the structure can vary. In the case of paperboard cylindrical packaging, it is not as intuitive as it seems. It can be said that paperboard tube packaging is a packaging with rich connotations.

1. Raw Materials for Paper Tube

The raw materials used are one of the factors affecting the price of paper tubes. It is well known that paper tubes are mainly made of paper. There are many types of paper that can be used as packaging paper, including white cardboard, gold cardboard, white paper, kraft paper, and copperplate paper, etc. Each type of paper has a different market price, which means that the price of paper tubes will vary depending on the type of paper used.

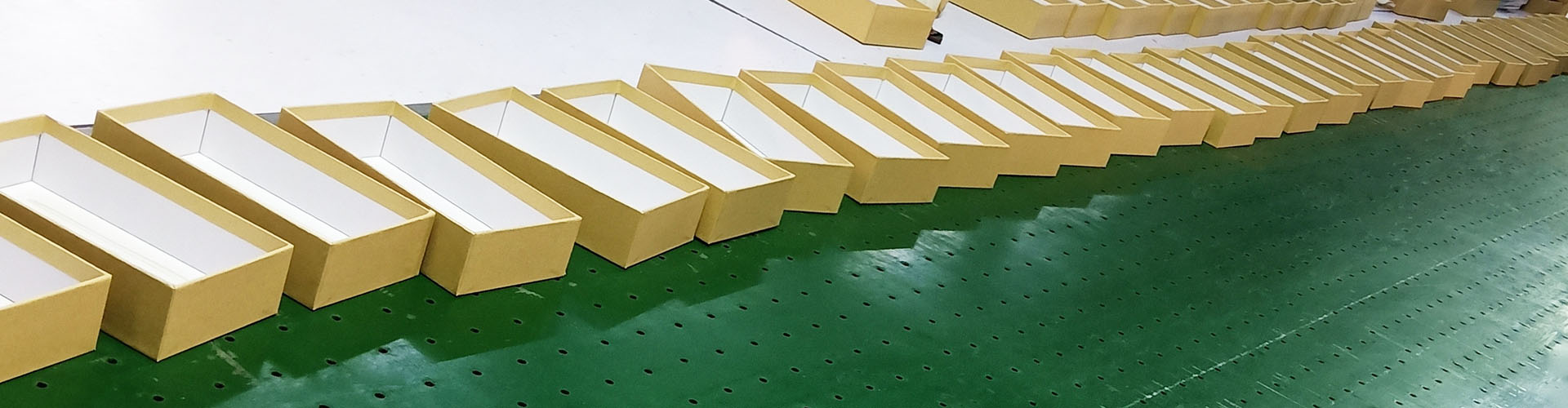

2. Wall Thickness of Paperboard Cylindrical Packaging

The wall thickness of paperboard cylindrical packaging refers to the thickness of the paperboard cylinder box. Those who have come into contact with paper can packaging know that the surface of paperboard cylindrical packaging is identical. When we squeeze the paperboard cylindrical packaging with our hands, some paper tubes will deform significantly, while others will not show much deformation. This difference is due to the different thicknesses of the paper walls in the paperboard cylindrical packaging.

3. Production Process of Paper Tubes

The production process of paper tube packaging is also one of the factors affecting its price. The more complex the production process, the more intricate the craftsmanship, and the corresponding production cost increases accordingly.

Of course, these are not the only factors that affect the price of paper tubes. The price of paper tube is also influenced by factors such as size, logistics, and label printing technology. Therefore, when customizing paper tubes, price is not the main consideration. It depends on the specific requirements of the paper tubes.

The price of paper tubes is influenced by factors such as raw materials, wall thickness, production process, size, logistics, and printing technology. Understanding these factors can help customers better understand why there may be minimal price differences between paper tubes with similar sizes and craftsmanship.

previous post

Why Cardboard is the Best Material for Product Packaging

next post

The production and demand of China's paper industry continue to grow

YOU MAY ALSO LIKE

What is sustainable packaging

2023-05-05 02:03:21

Customized Packaging Solutions with a Commitment to Sustainability

2023-07-15 07:23:59

Reducing Waste and Increasing Recycling

2023-07-18 04:01:48

Promote sustainable practices throughout the supply chain

2023-07-18 06:35:56

Focus on eco-friendly materials

2023-07-18 07:04:38

The packaging solution tailored for a specific product

2023-07-18 07:32:16POPULAR POSTS