Flexographic Printing

Flexographic printing, also known as flexo printing, is a printing process that uses flexible relief plates to transfer ink onto a substrate. The plates are made of a photopolymer material that is sensitive to light and can be molded into any shape or size. The ink is transferred by a series of rollers, including an anilox roller that controls the amount of ink delivered to the plate.

- Uses flexible relief plates to transfer ink onto a substrate

- Versatile and can print on a wide range of substrates

- Runs at high speeds, making it cost-effective for large print runs

- Offers excellent print quality with sharp, vibrant images and excellent color accuracy

- Uses high-quality photopolymer plates and advanced ink formulations

- Environmentally friendly due to the use of water-based inks and low-VOC solvents

- Ideal for packaging applications where different materials and designs are required.

The features of flexo printing are as follows:

1. Printing ink is a low viscosity volatile dry printing ink with alcohol and water as the main solvent, which has a fast drying speed and is suitable for flexographic high-speed multi-color printing. The application of water-based ink with no pollution and fast drying is very beneficial to environmental protection.

2. Flexographic plate is a photosensitive rubber or resin type printing plate, with soft, flexible and elastic characteristics. The Shore hardness is generally 25~60, and the transfer performance of the ink is good, especially for the alcohol solvent ink. This is the Shore hardness of more than 75 stereotype, plastic version can not be compared.

3. Use light printing press for printing.

4. The substrate material for flexographic printing is very wide.

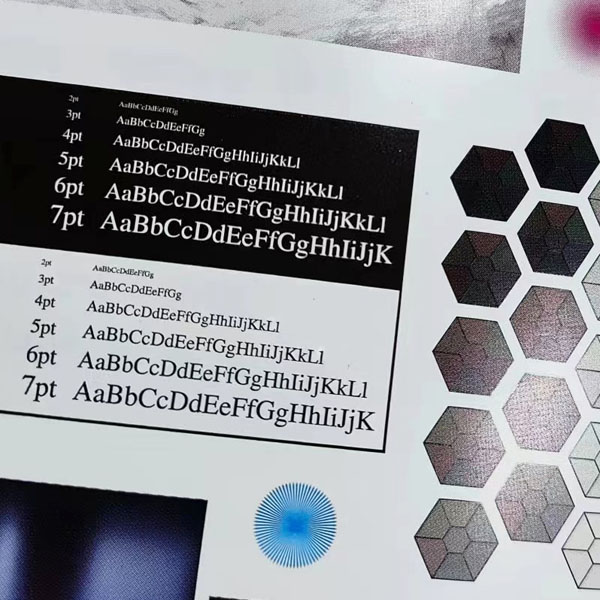

5. Good printing quality. Due to the high quality resin plate, ceramic roller and other materials, so that the printing accuracy has reached 175 lines /in, and has a full ink layer thickness, so that the product is rich in layers, bright colors, especially suitable for packaging printing requirements, its eye-catching color effect is often offset lithography can not be achieved. It combines the clarity of letterpress printing, the soft color of offset printing, and the thick and high gloss of gravure ink layer.

6. High production efficiency. Flexographic printing equipment usually adopts reel type materials, which can be completed continuously from double-sided multicolor printing to glazing, laminating, gilding, die-cutting, waste discharge, winding or slitter. In the lithography offset printing often need to use more personnel and multiple equipment with three or four processes to complete. Therefore, flexographic printing can greatly shorten the printing cycle, reduce costs, and give users an advantage in a highly competitive market.

7. Easy to operate and maintain. The printing machine adopts the roller inking system, which saves the complicated inking mechanism compared with the offset press and the letterpress, so that the operation and maintenance of the printing machine are greatly simplified, and the inking control and reaction are more rapid. In addition, the printing press is generally equipped with a set of plate drums that can adapt to different printing repeat lengths, especially to adapt to packaging prints whose specifications are often changed.

8. High printing speed. The printing speed is generally 1.5 to 2 times that of the offset press and gravure printing machine, which realizes high-speed multi-color printing.

9. Low investment and high return. Modern flexographic printing machine has the advantages of short ink transfer route, few ink transfer parts, and extremely light printing pressure, which makes the flexographic printing machine simple structure and saves a lot of materials used in processing. Therefore, the investment of the machine is much lower than that of the same color offset press, and it is only 30% to 50% of the investment of the same color gravure printing machine.